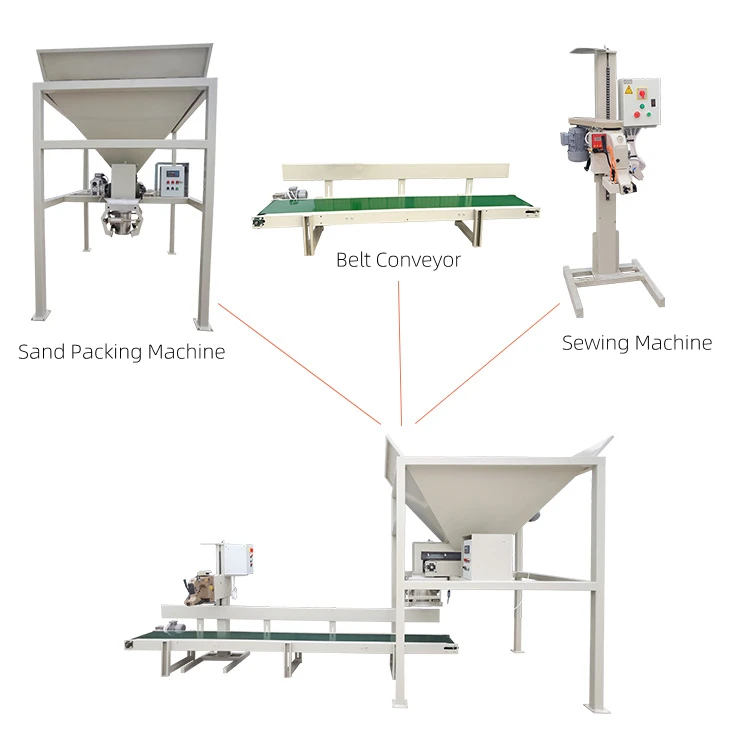

Description

Working principle

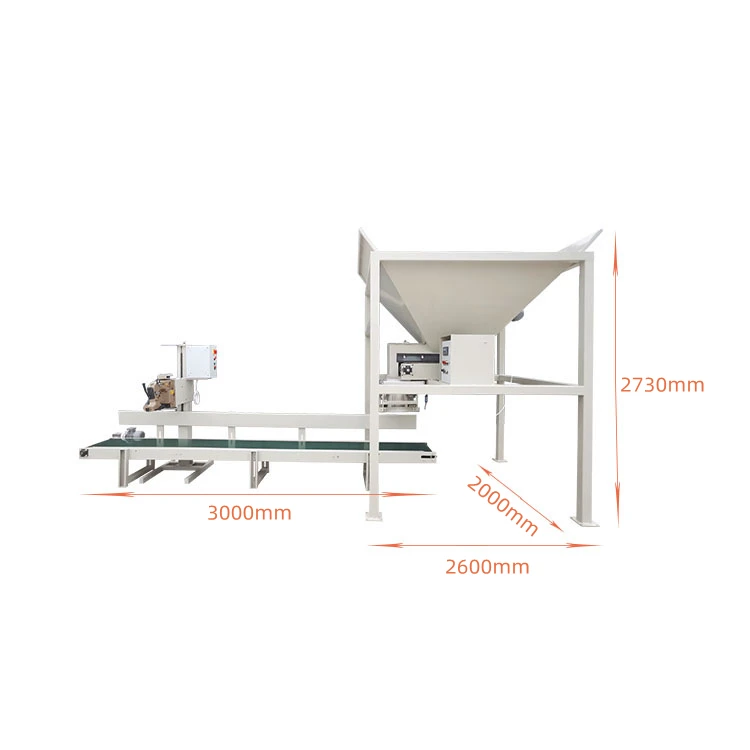

Hopper and outlet:the sand falls into the woven bag from the hopper through the outlet. The discharge port is provided with a solenoid valve to control the flow of sand.

Vibratory pendulum:set on the side wall of the hopper or fixed frame, used to prevent sand blockage or sticking to the wall.

Turntable and woven bag fixing seat:the turntable is provided with a plurality of woven bag fixing seats for fixing the woven bag to be loaded with sand. Each fixed seat is equipped with a through hole, an electromagnet and a metal press block, which is attached to the electromagnet when it is energized to help hold the woven bag.

Binding machine and weighing sensor:The binding machine is arranged under the turntable to seal the woven bag that has been filled with sand. The weight sensor is connected to the solenoid valve to automatically control the bagging amount, ensuring that the weight of each bag of sand is the same.

Performance characteristics

Efficient and stable feeding: The belt feeds at a uniform speed, the feeding speed is fast, and the measurement error is reduced. Accurate measurement: The high-precision sensor and control system work together to control the packaging weight error within ±0.2%. Easy operation: The humanized human-machine interface can be operated after simple training, reducing labor costs.

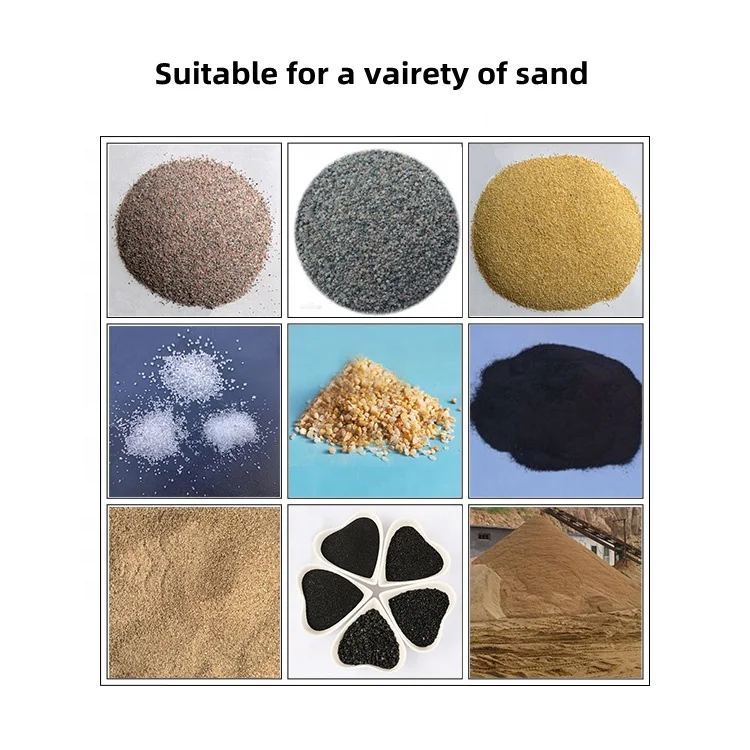

Applicable Materials

Sand (wet or dry), Soil (screened or native), Mulch or Compost, Gravel or Stone (up to 2″), Lava Rock or Cinder, Salt and Minerals, Wood Chips (up to 2″).

It is mainly used in the building materials industry to provide bagged sand for construction sites, mixing plants, etc. In road construction, it is used to package sand for paving the roadbed; in house construction, it provides packaged sand for wall building, plastering and other links for easy transportation and use.

There are no reviews yet.