Description

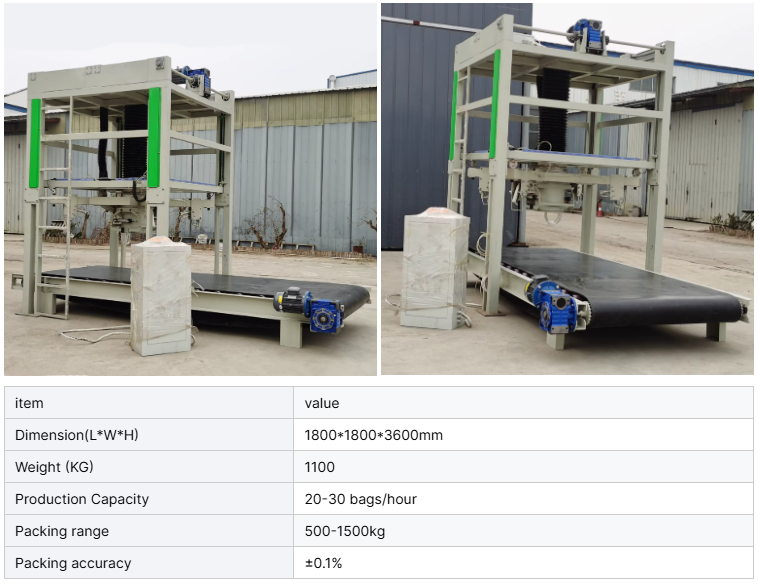

Ton Bag Packing Machine

Ton bag bagging machine is designed for powders or granules, with a packaging hopper, filling control system, and support platform installed above the machine. Load cells are used for weighing during the packaging process. Below the bagging machine, there is a automated conveyor.

The packaging machine is specialized equipment for quantitative irrigation, featuring dual screws and a precision valve inside the cylinder.

The operational process of packaging is automatically controlled by programmed logic; all procedures except bag hanging and bag release are completed automatically. The structural components of the equipment, from top to bottom, include: material delivery, precision control valve, dust collection receiver, support frame, weighing platform, support platform, lifting platform, pneumatic bag hanger, pneumatic pusher, machine frame, electrical control cabinet, access ladder, and guardrails. It is characterized by simple operation, high automation, high measurement accuracy, advanced and reliable structure, and high productivity.

Working Process

Material filling: Granular or powdered materials enter the packaging area of the ton bag packaging machine from the material storage area through the pipeline system.

Weighing stage: The warehouse is piped to the weighing system and accurately weighed by the weighing sensor to ensure that the supply quantity in each ton bag meets the requirements.

Weighing: The pallets that have been weighed are loaded into the ton bag according to the preset packaging weight.

Conveying: After filling is completed, the conveying device transports the packaged bulk bags to the designated location.

The ton bag packaging machine provides convenient and accurate storage and packaging solutions for various industries through automated operation, efficient production, accurate weighing, wide application, flexibility and reliability.

Application

Widely used in chemical, grain, feed and other industries, packaging various bulk materials in large bags, suitable for large-scale, high-efficiency packaging scenarios. Such as chemical packaging of plastic granules and fertilizers; building materials packaging of cement and sand; grain packaging of corn and wheat, etc.

There are no reviews yet.