To effectively enhance the market competitiveness of fully automatic packaging equipment, consider the following strategies:

- Technological Innovation: Continuously invest in research and development to improve equipment performance and functionality, staying ahead of market demands.

- Cost Reduction: Optimize production processes to lower manufacturing costs, making products more competitively priced.

- Quality Improvement: Ensure consistent and reliable product quality to boost customer satisfaction and build a strong brand reputation.

- After-Sales Service: Establish a comprehensive after-sales service system to promptly address customer needs and provide technical support and training.

- Marketing Strategies: Develop effective marketing plans to increase brand visibility and expand market share.

- Supply Chain Collaboration: Partner with reliable suppliers to ensure stable raw material sourcing and reduce production risks.

By implementing these methods, you can significantly improve the market competitiveness of fully automatic packaging equipment, attracting more customers and expanding your market presence. Wishing you success!

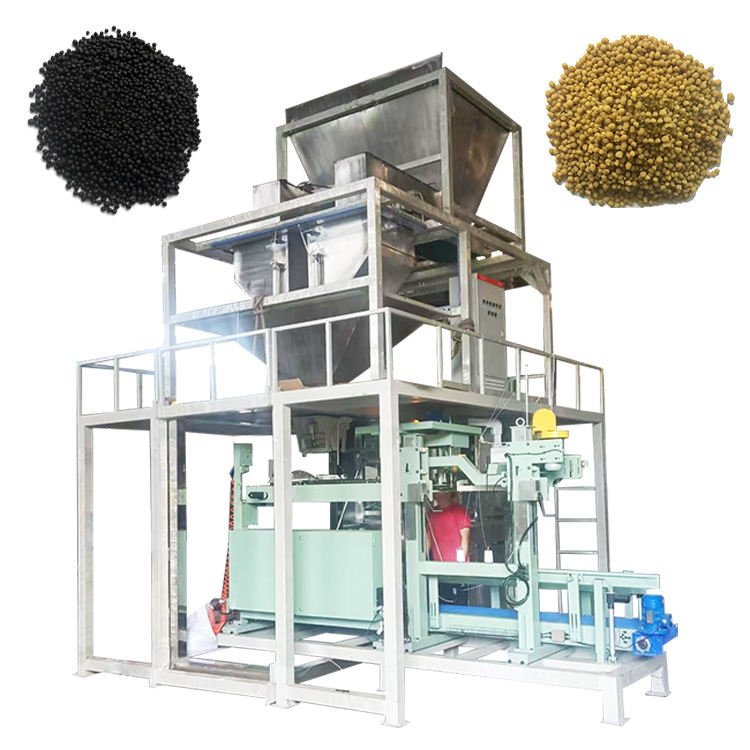

How Much Does Fully Automatic Packaging Equipment Cost?

The price of fully automatic packaging equipment varies significantly, typically ranging from tens of thousands to hundreds of thousands depending on production capacity requirements. Quotes differ among manufacturers due to variations in production techniques, material choices, and regional economic conditions. For reliable quality and after-sales support, it is advisable to choose established manufacturers like Zhengzhou Yuheng Technology Co., Ltd. Feel free to contact us for a customized quotation and professional assistance.

Leave a Comment

Your email address will not be published. Required fields are marked *